Check Valves

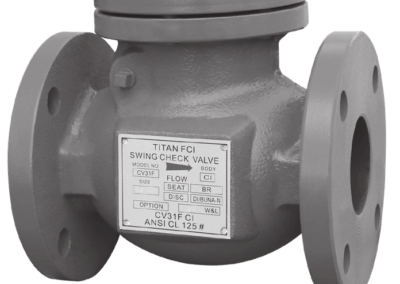

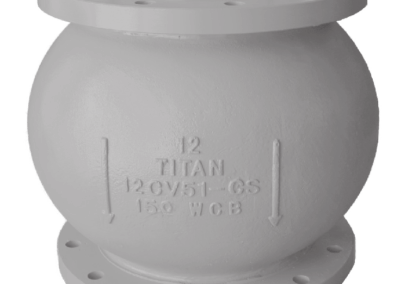

Swing Check Valves

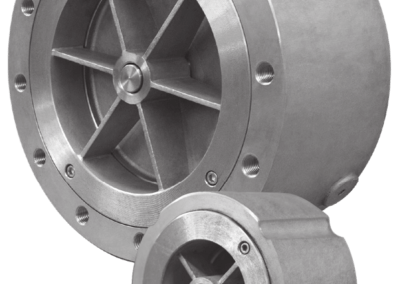

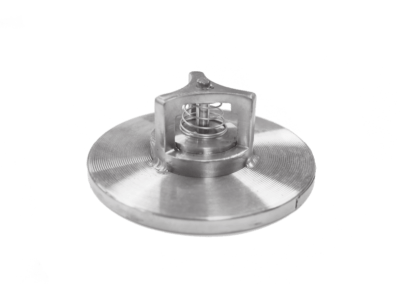

Piston / Lift Check Valves

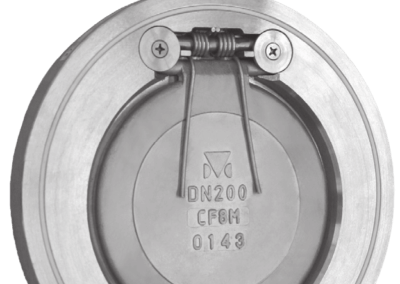

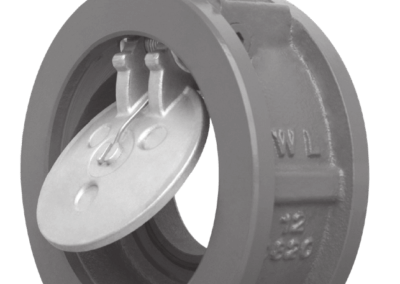

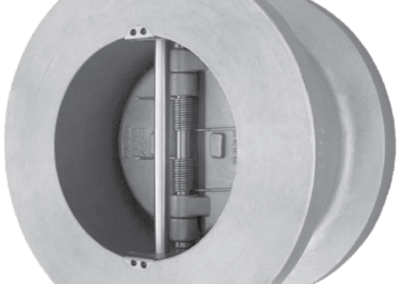

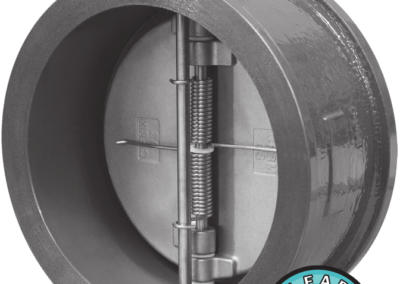

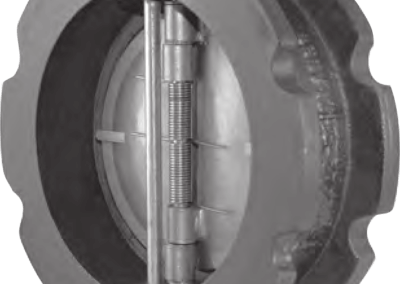

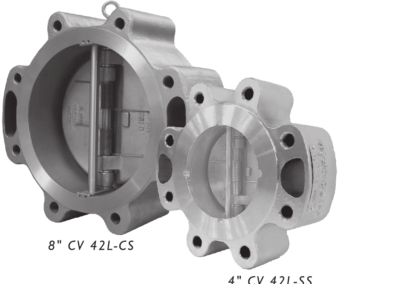

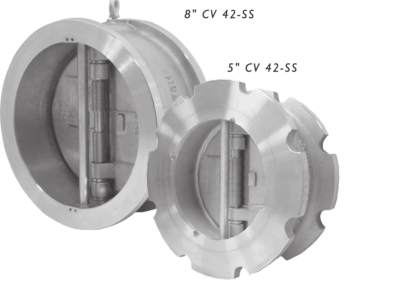

Wafer Check Valves

Why Check Valves?

The main goal of a check valve is to keep medium flowing in the proper direction. These must be installed per the arrow that is on the body to ensure the correct flow direction. There are also other uses for check valves such as to prevent backspin, water hammer and thermoacoustic oscillations.

Advantages of Check Valves

- Very low maintenance required

- Effective method for preventing water hammer or thermoacoustic oscillations

- Protection for pumps from reverse flow or pressure

- low footprint, especially with wafer check valves

- Open and close automatically as flow stops/starts

Disadvantages of Check Valves

- Not recommended for use with constantly variable on/off due to wear on the seats or springs

Types of Check Valves Available

- Swing

- These valves have a swinging plug internally and can be opened for maintenance/cleaning

- Lift / Piston

- Very low profile valves that have all integral parts. The spring in this valve re-seats at very low flows/pressures and gives a positive seal. Piston check valves are typically specified with a cracking pressure number.

- Wafer

- Check Valves that are held between two flanges. Easy maintenance and installation.

For More Information on Check Valves

Feel free to contact us and we will assist with selection given your exact application and specification.

Contact Us

General Contact Information

Located near Chicago, IL just east of the 55/294 Interchange.

If you would like to learn more about what we have to offer

at Accurate Valve Automation, Inc.,

please contact us via one of the methods below and

we'll get back to you as soon as possible.