Filter / Strainer Guide

What is a strainer, and strainer vs filter?

A strainer is a device which removes particulate from the main process stream. The difference between a filter and a strainer can simply be explained in relation to the particulate size that is being collected. Typically a filter is removing small particles, while a strainer is collecting larger debris. Strainers can also be configured with a mesh particulate filter inside the catch basket. In all cases, filters and strainers have a method of cleaning, which is unique to each type of filter.

Advantages of Wye Strainers

- Advantages

- Cost efficient

- Can be equipped with blow-down valves to remove debris without removing the full strainer

- Small footprint which allows for many mounting options

Advantages of Simplex Strainers

- Advantages

- Larger Straining capacity vs wye strainers

- Typically have a large opening on the top of the unit for easier cleaning.

Advantages of Duplex Strainers

- Advantages

- Largest straining capacity

- Two filters within the same body, with one filter in use at a time

- Can clean one filter as the other is still flowing/straining

- Large removable cap on top for cleaning/maintenance

For More Information on Filters or Strainers

Feel free to contact us and we will assist with selection given your exact application and specification.

Most Important Factor

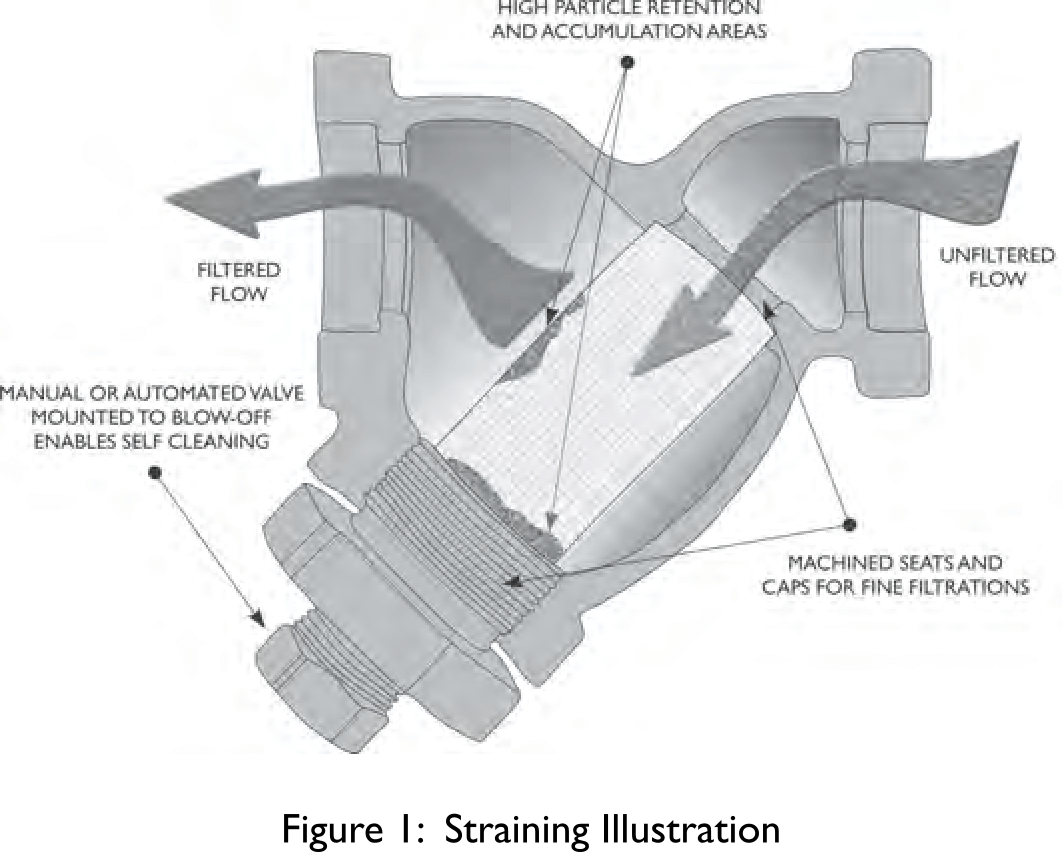

Specifying the Mesh or Perforation Size for the straining element. The straining element is the mechanical filter that collects and obstructs the particles too small to pass through, but allows the process medium to continue. By cleaning the process flow, the strainer/filter protects downstream components such as pumps and other expensive equipment. Figure 1 shows a typical Wye Strainer’s functional flow characteristic.

Image Courtesy of Titan Flow Control, Inc.

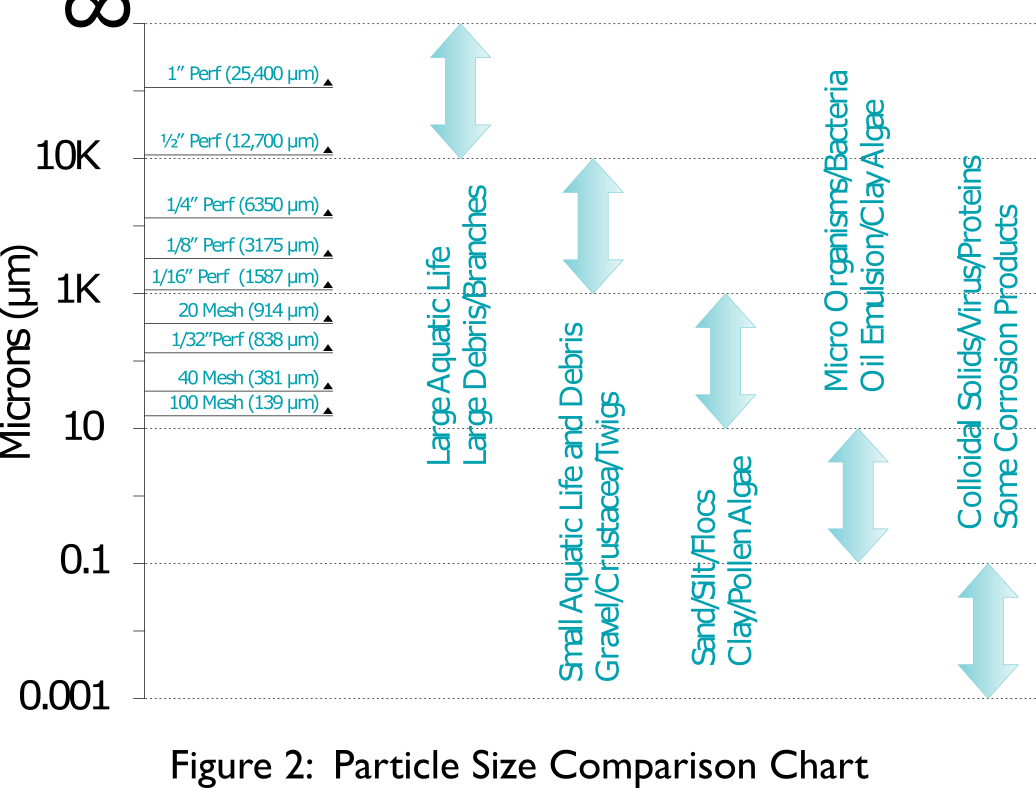

Choosing Pore Size

In general, screen openings should be approximately one-half the diameter of the largest allowable particle. The largest allowable particle is defined as the size of particle that can pass through downstream equipment without causing damage. For example, if the maximum allowable particle is 1/16 inch than the screen opening would be specified at 1/32 inch. In addition to the size of particles, the quantity of debris in the flowing media must also be considered when determining the appropriate opening size. For a Particle Size Comparison Chart, See Figure 2. See Table 1 for general guidelines in selecting pore size.

For your reference, below is a chart to convert Mesh/Micron/Inch Pore Sizes.

| U.S. Mesh | Micron | Pore Size (Inches) |

| 3 | 6730 | 0.265 |

| 4 | 4760 | 0.187 |

| 5 | 4000 | 0.157 |

| 6 | 3360 | 0.132 |

| 7 | 2830 | 0.111 |

| 8 | 2380 | 0.0937 |

| 10 | 2000 | 0.0787 |

| 12 | 1680 | 0.0661 |

| 14 | 1410 | 0.0555 |

| 16 | 1190 | 0.0469 |

| 18 | 1000 | 0.0394 |

| 20 | 841 | 0.0331 |

| 25 | 707 | 0.028 |

| 28 | 700 | 0.028 |

| 30 | 595 | 0.0232 |

| 35 | 500 | 0.0197 |

| 40 | 420 | 0.0165 |

| 45 | 354 | 0.0138 |

| 50 | 297 | 0.0117 |

| 60 | 250 | 0.0098 |

| 70 | 210 | 0.0083 |

| 80 | 177 | 0.007 |

| 100 | 149 | 0.0059 |

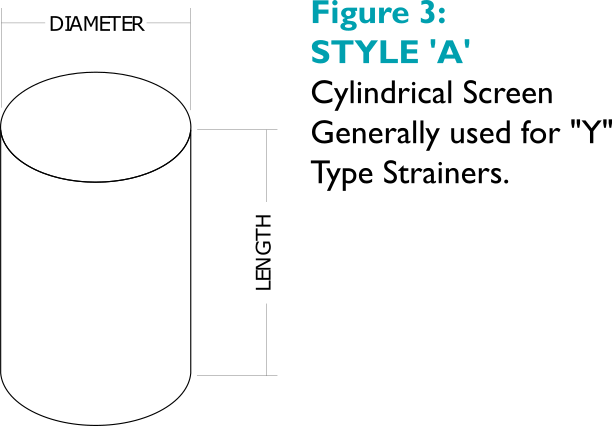

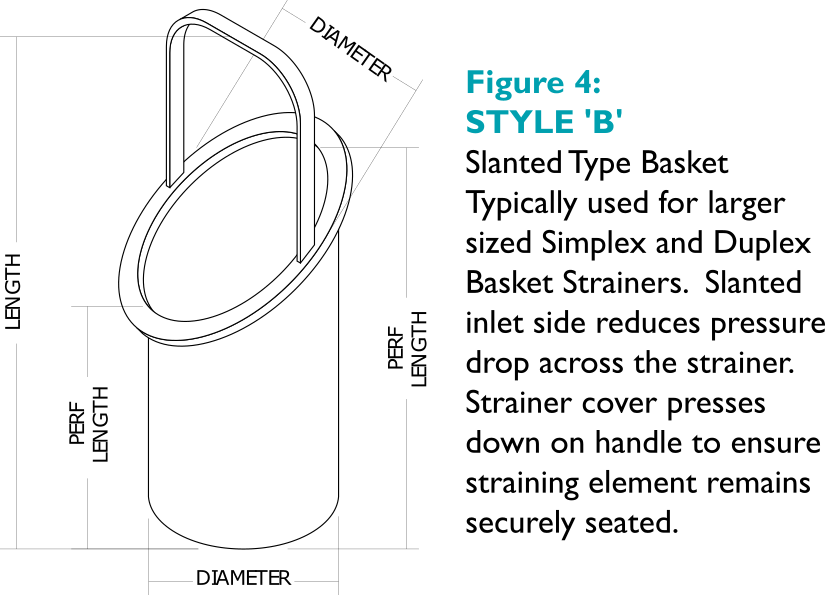

Strainer Element Configurations - Standard Designs Available

Wye, “T” and Basket Strainers can be manufactured in a variety of shapes, sizes and materials. Below are some examples of those that can be provided. Additionally custom manufactured strainers, that do not match one of the below shapes perfectly, are possible. If you have a strainer that requires a new element, please contact us.

Images Courtesy of Titan Flow Control, Inc.

Contact Us

General Contact Information

Located near Chicago, IL just east of the 55/294 Interchange.

If you would like to learn more about what we have to offer

at Accurate Valve Automation, Inc.,

please contact us via one of the methods below and

we'll get back to you as soon as possible.