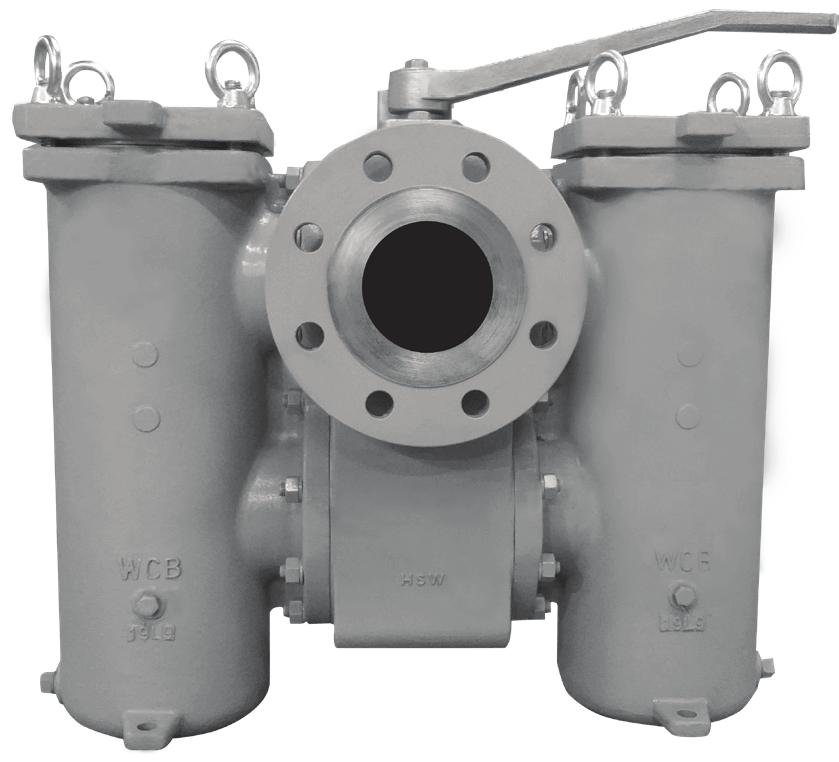

Flanged and Screwed End CS SS Class 300 DS796/896

Model Highlights

MODEL DS796/896 | Class 300 | 3/4” thru 4″

• FEATURES •

– Epoxy Painted

– Gasketed Caps

– Dual-Ball Diverter Design

• OPTIONS •

– Screen Mesh

– Alternative Materials Available

Titan Flow Control, Inc. was established in 2000 by a group of industry veterans with over 300 years of combined experience. Since then, the highly qualified management team has built a solid company that is known worldwide for its quality products and unmatched customer service.

Product Description

Duplex Strainers are unique products within the pipeline industry. Like other basket strainers, the duplex strainer protects downstream components from harm by mechanically removing solids from the flowing fluids via perforated filter materials. Routine maintenance of checking seals and emptying the baskets is all that is required to keep your duplex strainers in a prime working condition. Titan Flow Control, Inc. manufactures an excellent choice of Duplex Strainer that is readily available in some sizes, and with very available elements/maintenance equipment. Please contact us for more information on ordering today.

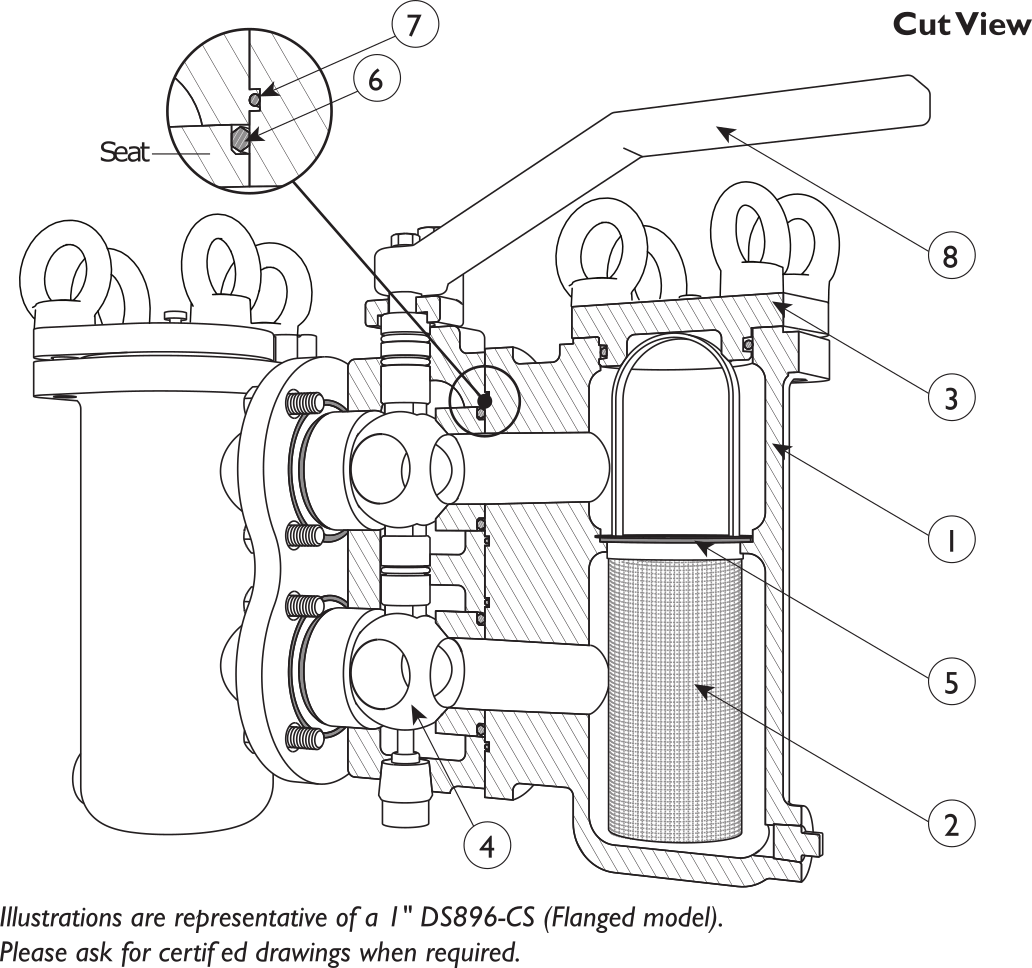

| DS796/896 DUPLEX STRAINER BILL OF MATERIALS | |||

|---|---|---|---|

| ITEM | DESCRIPTION | DS 796/896-CS | DS 796/896-SS |

| 1 | Main Body / Basket Housing | Carbon Steel A216 Gr. WCB | Stainless Steel A351 Gr. CF8M |

| 2 | Straining Element | Stainless Steel | Stainless Steel |

| 3 | Cover | Carbon Steel A216 Gr. WCB | Stainless Steel A351 Gr. CF8M |

| 4 | Ball | Stainless Steel | Stainless Steel |

| 5 | O-Ring Straining Element | Buna-N | Viton |

| 6 | Seat Seal | Teflon (PTFE) | Teflon (PTFE) |

| 7 | Seals | Buna-N | Viton |

| 8 | Handle | Carbon Steel, Zinc Coated | Carbon Steel, Zinc Coated |

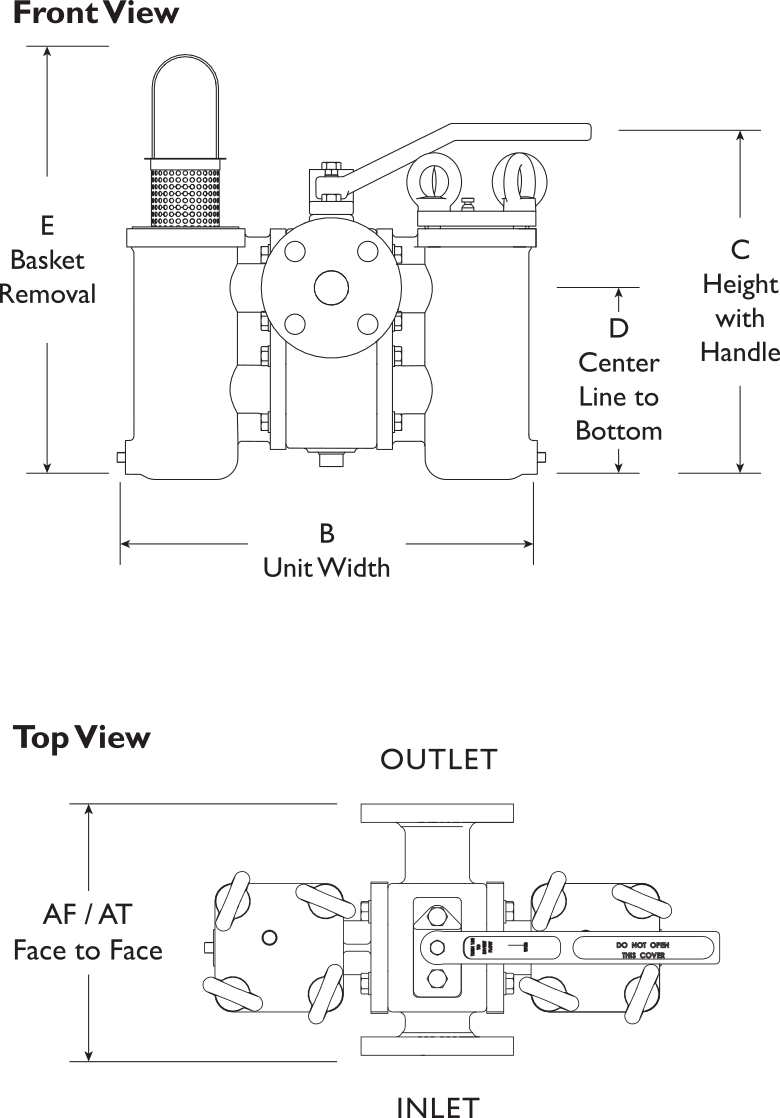

| DS796/896 DUPLEX STRAINER DIMENSIONS & WEIGHTS | |||||||||

|---|---|---|---|---|---|---|---|---|---|

| SIZE (in) | AF (in) FLANGED FACE TO FACE | AT (in) THREADED FACE TO FACE | B (in) UNIT WIDTH (INCLUDES PLUG) | C (in) HEIGHT WITH HANDLE | D (in) CENTER LINE TO BOTTOM | E (in) BASKET REMOVAL | WEIGHT (FLANGED) (lb) | WEIGHT (THREADED) (lb) | FLOW COEFFICIENT (Cv) |

| 3/4 | 5.59 | 12.95 | 11.0 | 5.83 | 15.4 | 43.7 | 13 | ||

| 1 | 7.40 | 5.59 | 12.95 | 11.0 | 5.83 | 15.4 | 46.3 | 43.0 | 14 |

| 1 1/4 | 9.84 | 7.5 | 15.12 | 14.2 | 8.3 | 21.3 | 73.9 | 69.9 | 19 |

| 1 1/2 | 9.84 | 7.5 | 15.12 | 14.2 | 8.3 | 21.3 | 73.9 | 69.5 | 24 |

| 2 | 11.18 | 10.0 | 18.43 | 17.7 | 10.7 | 26.4 | 121.3 | 119.0 | 42 |

| 2 1/2 | 14.28 | 11.5 | 22.05 | 22.0 | 13.7 | 35.0 | 237.0 | 227.0 | 68 |

| 3 | 14.28 | 11.5 | 22.0 | 22.0 | 13.7 | 35.0 | 238.1 | 105 | |

| 4 | 16.61 | 26.85 | 25.2 | 15.9 | 41.0 | 373.7 |

Why Choose Accurate Valve Automation, Inc.?

Accurate Valve Automation has the experts you need at a reasonable price. We intend to continue providing, just as we have for 15+ years, solutions to our market segments. Ultimately we want to provide more than a simple product sale, and instead a solution to any industry’s flow, filtering, or process concerns.

Disclaimer

The above product specifications are provided as reference based on the latest information from the listed manufacturer. This information can not be guaranteed by Accurate Valve Automation without verification from the manufacturer prior to ordering. Please contact us if your application requires very tight tolerances or borderline pressure/temperature ratings for a review.

Contact Us

General Contact Information

Located near Chicago, IL just east of the 55/294 Interchange.

If you would like to learn more about what we have to offer

at Accurate Valve Automation, Inc.,

please contact us via one of the methods below and

we'll get back to you as soon as possible.