Flanged CS and SS Class 600 Y-Strainer Series YS64

Model Highlights

MODEL YS64 | Class 600 | 2” thru 12″

• FEATURES •

– Epoxy Painted

– Gasketed Caps

– Plugged Blow-off

– Large Straining Capacity

– Gauge Taps

• OPTIONS •

– Screen Mesh

– Blow-off Valve

Titan Flow Control, Inc. was established in 2000 by a group of industry veterans with over 300 years of combined experience. Since then, the highly qualified management team has built a solid company that is known worldwide for its quality products and unmatched customer service.

Product Description

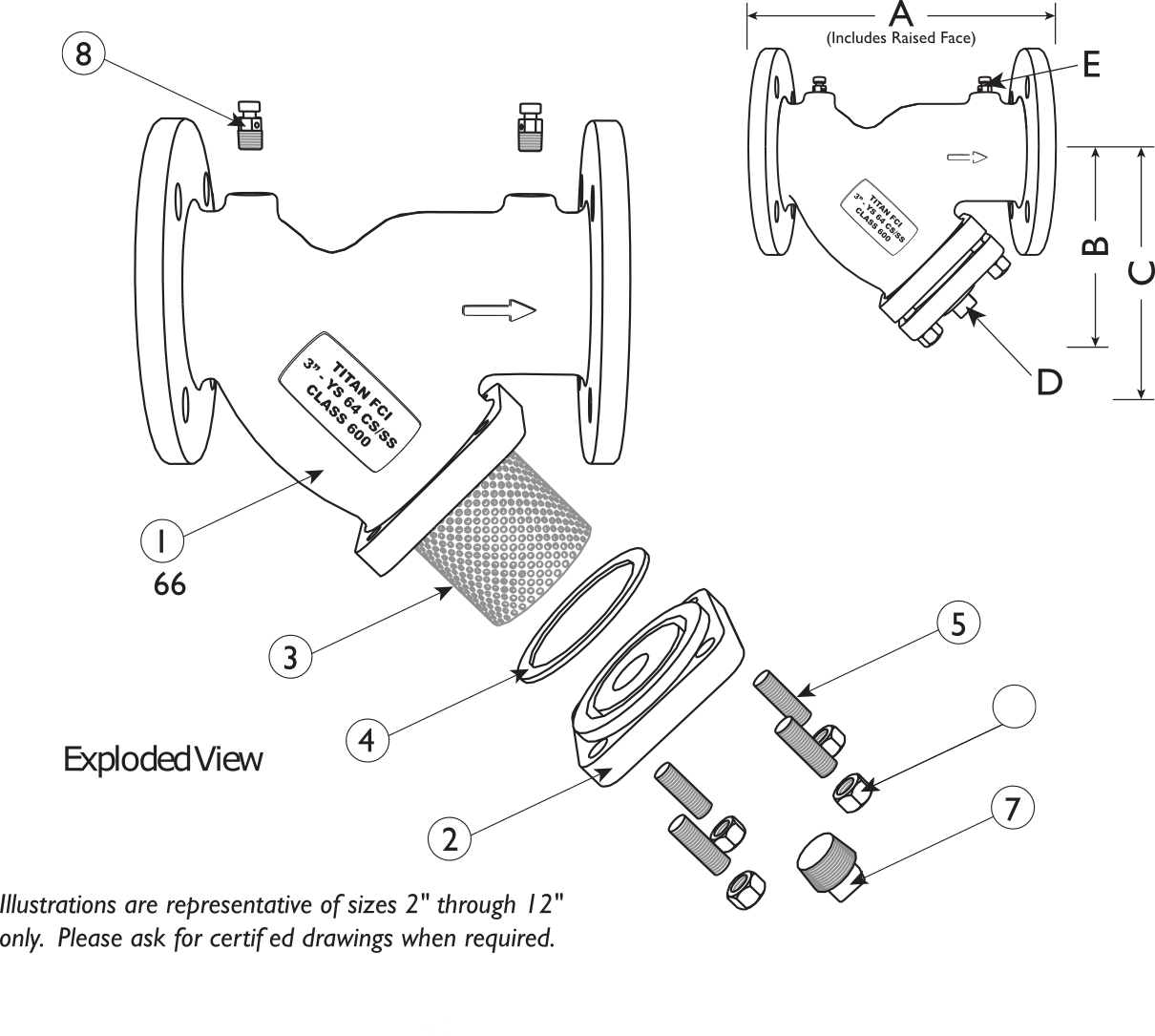

Titan Flow Control, Inc. manufactures this wye strainer with performance/versatility in mind. with its large body and sizable straining element, the YS64 provides excellent open area ratios that are typically 2.5 times larger than the process pipeline. All units are epoxy painted to prevent corrosion. There are other optional cover designs available such as swing, clamp and hinge type covers.

| YS64 Y (WYE) STRAINER BILL OF MATERIALS | |||

|---|---|---|---|

| ITEM | DESCRIPTION | YS64-CS | YS64-SS |

| 1 | Body | Carbon Steel A216 Gr. WCB | Stainless Steel A351 Gr. CF8M |

| 2 | Cover | Carbon Steel A216 Gr. WCB | Stainless Steel A351 Gr. CF8M |

| 3 | Straining Element | Stainless Steel | Stainless Steel |

| 4 | Gasket | Stainless Steel, Spiral Wound | Stainless Steel, Spiral Wound |

| 5 | Studs | Alloy Steel | Stainless Steel |

| 6 | Nuts | Alloy Steel | Stainless Steel |

| 7 | NPT Plug (Blow-Off) | Carbon Steel | Stainless Steel |

| 8 | NPT Plug (Gauge Tap) | Carbon Steel | Stainless Steel |

| YS64 Y (WYE) STRAINER DIMENSIONS & WEIGHTS | |||||||

|---|---|---|---|---|---|---|---|

| SIZE (in) | A (in) FACE TO FACE | B (in) CENTER LINE TO BOTTOM | C (in) SCREEN REMOVAL | D (NPT) BLOW-OFF | E (NPT) GAUGE TAPS | WEIGHT (lb) | FLOW COEFFICIENT (Cv) |

| 1/2 | 6.62 | 3.50 | 5.00 | 3/8 | N/A | 7.5 | C/F |

| 3/4 | 8.31 | 3.75 | 5.00 | 1/2 | N/A | 7.5 | C/F |

| 1 | 8.31 | 3.75 | 5.00 | 1/2 | N/A | 13.5 | C/F |

| 1 1/4 | 10.12 | 5.50 | 8.00 | 1/2 | N/A | 26.0 | C/F |

| 1 1/2 | 10.25 | 5.50 | 8.00 | 1/2 | N/A | 25.0 | 42 |

| 2 | 11.00 | 7.00 | 10.00 | 1/2 | 1/4 | 32.0 | 70 |

| 2 1/2 | 12.00 | 8.25 | 12.50 | 1 | 1/4 | 50.0 | 110 |

| 3 | 13.50 | 9.25 | 14.50 | 1 | 1/4 | 65.0 | 160 |

| 4 | 17.93 | 12.50 | 19.50 | 1 1/2 | 1/4 | 125.0 | 260 |

| 5 | 22.25 | 15.00 | 23.00 | 2 | 1/4 | 254.0 | 400 |

| 6 | 25.62 | 20.00 | 31.00 | 2 | 1/4 | 304.0 | 570 |

| 8 | 31.75 | 24.00 | 38.50 | 2 | 1/4 | 526.0 | 950 |

| 10 | 37.68 | 28.50 | 45.50 | 2 | 1/4 | 1090.0 | 1600 |

| 12 | 40.00 | 29.31 | 44.00 | 2 | 1/4 | 1558.0 | 2200 |

Why Choose Accurate Valve Automation, Inc.?

Accurate Valve Automation has the experts you need at a reasonable price. We intend to continue providing, just as we have for 15+ years, solutions to our market segments. Ultimately we want to provide more than a simple product sale, and instead a solution to any industry’s flow, filtering, or process concerns.

Contact Us

General Contact Information

Located near Chicago, IL just east of the 55/294 Interchange.

If you would like to learn more about what we have to offer

at Accurate Valve Automation, Inc.,

please contact us via one of the methods below and

we'll get back to you as soon as possible.